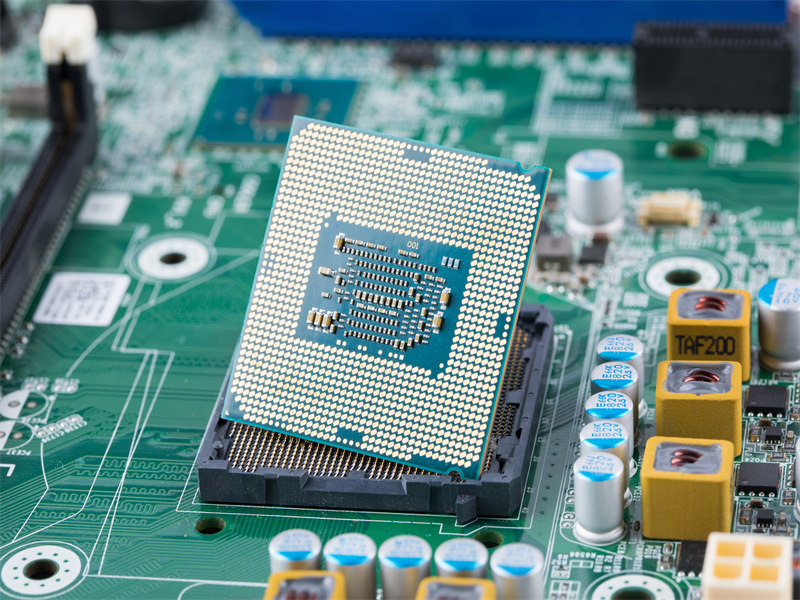

What is BGA (Ball Grid Array)?

BGA (Ball Grid Array) is a surface-mount packaging technology primarily used for integrated circuits. In this packaging method, the electrical connections are formed by tiny solder balls located on the underside of the package, arranged in a grid-like pattern. These balls connect to corresponding pads on the circuit board.

Compared to traditional packaging types such as DIP (Dual In-line Package) or QFP (Quad Flat Package), BGA offers several advantages:

• Higher pin density for more compact and complex designs

• Improved heat dissipation, making it suitable for high-performance components

• Lower electrical inductance, resulting in better signal integrity at high speeds

The BGA assembly process involves the precise placement and soldering of the BGA component onto the PCB, usually using automated machines for accuracy and efficiency. Additional steps such as cleaning, inspection, and testing are also carried out to ensure the quality and reliability of the assembled product.

BGA Capability

•Dense grid arrays with package sizes up to 35 × 35 mm

•Minimum ball pitch between 0.3 mm and 0.5 mm

•I/O counts of up to 1500 pins

•Support for high-speed signal routing on the PCB top layer

Advantages of BGA Technology

BGA technology enables a greater number of pins to be accommodated within the same footprint compared to traditional packaging methods.

This allows for higher integration and smaller chip designs, contributing to the miniaturization of electronic devices.

Short and uniformly distributed connections reduce signal transmission path lengths, minimizing parasitic inductance and capacitance.

This helps to prevent signal loss and distortion, ensuring stable and reliable performance — especially in high-frequency applications.

BGA packages offer better thermal conductivity between the chip and PCB.

The array of solder balls acts as a heat dissipation channel, effectively reducing hot spot temperatures, improving thermal balance, and extending component lifespan.

The relatively large pin spacing and self-alignment characteristics of BGA packages make them easier to assemble using standard SMT equipment.

This improves the reliability of the welding process and reduces the risk of assembly defects.

With no protruding pins, BGA packages are less prone to physical damage like bending or breaking.

The solder ball array distributes mechanical stress evenly, making the package stable even in demanding environments.

BGA technology is compatible with various materials and design configurations, making it suitable for a wide range of applications across industries.

BGA PCBA Project

Email :

Sales@dqspcba.comOur hours

24H