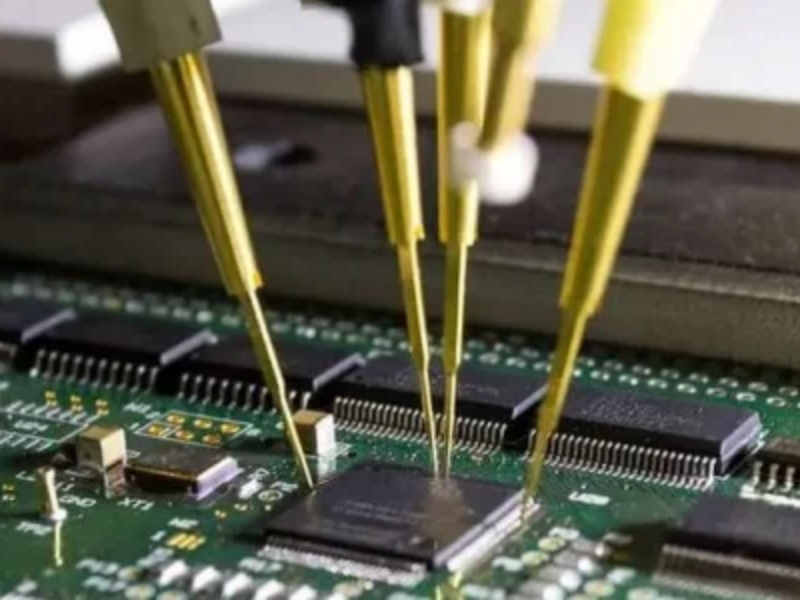

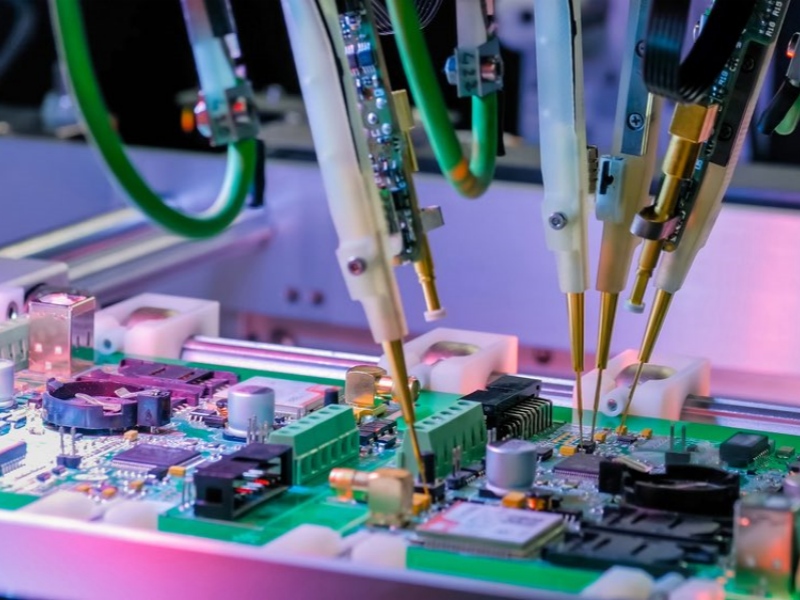

PCBA functional testing simulates real-world operating conditions to evaluate whether the assembled circuit board performs correctly according to its predefined program. During this process, the electrical connectivity and signal behavior of the electronic components are assessed by checking input and output values. This ensures that the board functions as intended.

Functional testing helps prevent manufacturing defects and quality issues, reducing unnecessary repair costs and ensuring that only fully functional products are delivered to customers — improving satisfaction and reliability. Additionally, functional testing plays an important role in optimizing PCB design by detecting and resolving potential defects early in the process. This significantly enhances the reliability and stability of the product while minimizing the risk of failure.

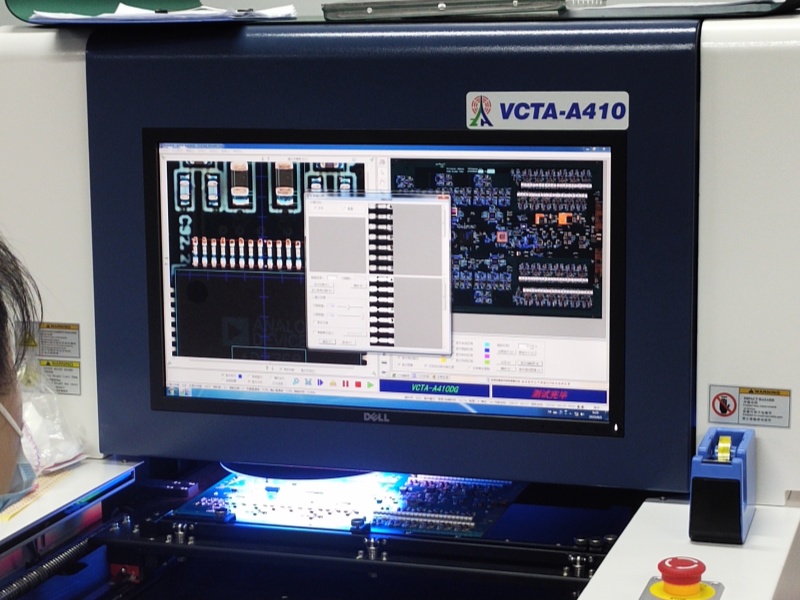

For high-volume PCBA testing, specialized test fixtures are often used to increase efficiency. These fixtures connect test probes to designated test points on the board. Once power is applied, the fixture measures key parameters like voltage and current and displays them on a monitor, allowing for quick verification. To support this, PCB designers must plan for testing early by reserving test points and supplying complete test documentation or procedures.

Automatic Conformal Coating

For electronic assemblies operating in harsh environments — such as high humidity, salt exposure, dust, and vibration — PCBAs can be vulnerable to damage caused by moisture, salt spray, or mold. This can lead to system failure. DQS offers an automated conformal coating process that provides protective coverage to enhance product durability and environmental resistance.

Your Quality Assurance Partner

At DQS Electronic Group, we offer a full range of PCB and assembly testing services to ensure that your electronic products meet the highest quality and reliability standards.

Email :

Sales@dqspcba.comOur hours

24H