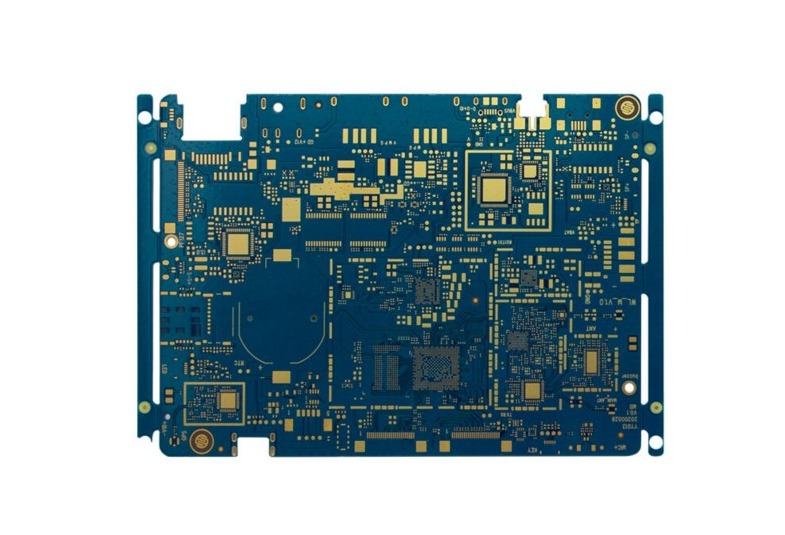

Layer :

8Material :

TG170Board Thickness :

1.2mmMin. Line Width/Space :

0.1/0.1mmSurface Finish :

Immersion GoldApplication :

WIFI ModuleCertificate :

UL&IPC Standard &ISO

What Is an HDI PCB?

HDI (High-Density Interconnect) printed circuit boards are advanced PCBs with high circuit distribution density. They are manufactured using technologies such as micro-blind vias, laser drilling, electrochemical hole filling, and stacked via structures.

Advantages of HDI PCBs:

High density: Compared with traditional PCB boards, HDI boards have a higher wiring density, which effectively improves the complexity of circuit design and reduces the size of the product.

High reliability: HDI boards have excellent heat resistance, humidity resistance and electrical properties, ensuring the long-term stable operation of electronic equipment.

Excellent electrical and thermal properties: HDI sheet has a low dielectric constant and low coefficient of thermal expansion, which effectively improves the transmission speed of electrical signals and ensures the stable operation of electronic equipment in various environments

Application:

HDI printed circuit boards are widely used in communication equipment, computers, consumer electronics, automotive electronics, and other electronic devices to meet the needs of high-speed data transmission, multi functionalintegration, and small-size design in these fields. It is also widely used in medical equipment, aerospace and defence due to its high wiring density and high reliability.

DQS Electronic has introduced high-precision manufacturing equipment, using advanced machinery, excellent metal base materials, and ultra-thick copper processing techniques. We maintain a first-class production line to ensure processing accuracy and quality.

Whether standard or highly complex PCBs – no matter how challenging – simply send us your PCB file, and our engineers will provide a suitable solution.

|

Item |

HDI PCB Capability |

|

Layer |

4-64 L |

| HDI Structure |

1+N+1, 2+N+2, 3+N+3 or any layer interconnection |

|

HDI AVI |

Blind through holes, buried through holes, staggered through holes, stacked through holes, skip through holes |

|

Min. Hole Size |

0.075mm |

|

Min. Line Width/Space |

Rigid PCBs: 2mil/2mil ; Flex PCBs0.025 / 0.025mm |

|

Dielectric Thickness |

Max:0.2mm ; Min:0.06mm |

|

HDI PCB Production Capability |

200000m²/month |

|

Inner copper thickness |

0.5-15oz or more |

|

Outer copper thickness |

0.5-10oz |

|

Surface Finish |

OSP HASL: SMD 40µ to 2000µ’, GND 30µ to 800µ’ ENIG: Au 1µ to 5µ’, Ni 80µ to 200µ’ Immersion Tin: 0.8µm to 1.2µm Immersion Silver: 0.15µm to 0.45µm Hard gold plating: Au 1µ to 50µ’, Ni 80µ to 200µ’ Peelable film: 5mil Carbon Ink: 0.3mil |

Our hours

24H