In the PCB industry, EMS (Electronic Manufacturing Service) also known as ECM or professional electronic manufacturing services. Refers to a company that provides a comprehensive range of services to take a printed circuit board (PCB) from a design file to a fully assembled and tested final product. They are essentially the manufacturing partner for companies that design electronics.

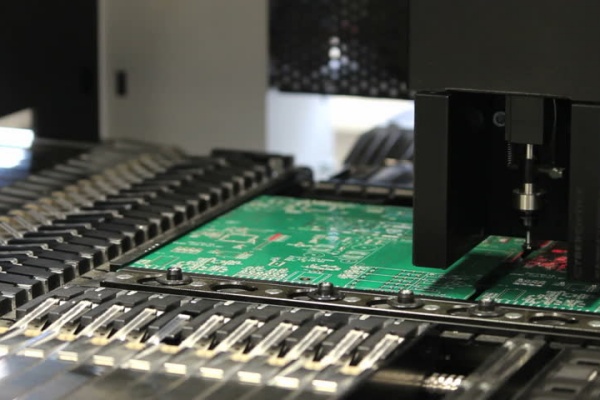

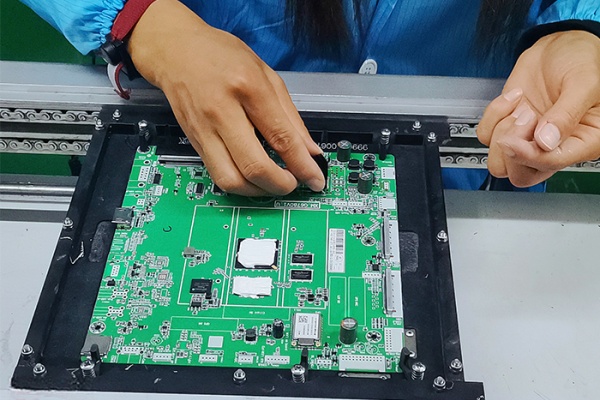

(DQS EMS FACTORY)

The EMS industry emerged in the late 1970s. At that time, most electronics manufacturing, especially large-scale product manufacturing, was largely handled in-house. The EMS business model specialized in large-scale, economies-of-scale production, raw material sourcing and centralized resources, specialized industrial design solutions, and creating value-added services such as warranty and repair. This freed up customers with large inventories. Therefore, they could respond more quickly and efficiently to sudden peaks in demand, developing surface mount technology (SMT) printed circuit boards (PCBs) for rapid assembly of electronic products. The early 1990s saw OEMs rapidly installing SMT production lines. By the mid-1990s, the advantages of the EMS concept became apparent, and OEMs began outsourcing printed circuit board assembly (PCBA) on a large scale. By the end of the 1990s and early 2000s, many OEMs sold their assembly plants to aggressively pursue EMS market share. A wave of consolidation followed, allowing more cash-washed companies to quickly acquire existing plants and smaller EMS companies.

(DQS EMS FACTORY)

PCBs also known as printed circuit boards, are important electronic components. They serve as the support for electronic components and provide the connections between them. Because they are manufactured using electronic printing technology, they are called "printed" circuit boards. PCBA is an abbreviation for Printed Circuit Board Assembly. Simply put, PCBA can be a series of processes consisting of SMT (Surface Mount Technology) assembly, DIP (Dual In-line Package) assembly, and PCBA testing.

SMT (Surface Mount Technology) assembly is the process of mounting electronic components onto a bare PCB board. The PCB undergoes solder paste printing, component mounting, reflow soldering, manual soldering, AOI (Automated Optical Inspection) testing, and quality control. Then comes DIP (Dual In-line Package) assembly.

DIP assembly involves inserting non-mountable electronic components into the PCB, followed by wave soldering, lead trimming, and other quality control processes. At this point, most of the PCBA (Printed Circuit Board Assembly) fabrication is complete. Finally, testing and programming are performed to complete the entire manufacturing process.

EMS actually encompasses both OEM and ODM, and OEM and ODM further include PCBA. Therefore, PCBA manufacturing processes are essentially a component of EMS. Compared to PCBA, EMS has a higher level of technological difficulty and complexity, requiring a more advanced technical foundation.

What are the differences between EMS, OEM, and ODM?

OEM (Original Equipment Manufacturer). Also known as "contract manufacturing" or "OEM production." This business model has been operating effectively internationally for many years. To maximize the allocation of resources to innovation and minimize investment in fixed assets, companies do not directly engage in production but outsource production to other companies. This way, they only need to pay for material costs and processing fees, without bearing the burden of equipment depreciation and building their own factories. They can flexibly place orders based on market changes. This can foster new competitive advantages in finished goods business, cultivate and strengthen the company's internal expansion capabilities, improve operational capabilities and management levels, thereby creating conditions and accumulating experience for higher-level capital operations. ODM (Original Design Manufacturer). It can provide customers with a full range of services from product development, design, and manufacturing to after-sales maintenance.

Customers only need to provide the ODM service provider with the product's functions, performance, or even just a product concept, and the ODM service provider can turn the product from idea into reality. Compared to traditional OEM or ODM services that only provide product design and contract manufacturing, EMS providers offer knowledge and management services, such as materials management, logistics, and even product repair services.

Our hours

24H