Printed Circuit Boards (PCBs) are the backbone of modern electronics, powering everything from smartphones to aerospace systems. As the demand for advanced electronics grows, manufacturers worldwide seek reliable, high-quality, and cost-effective PCB production solutions. China has emerged as the undisputed leader in PCB manufacturing, offering cutting-edge technology, competitive pricing, and rapid turnaround times.

Why China is the Top Choice for PCB Manufacturing?

1. Unmatched Production Capacity & Scale

China is home to over 60% of the world’s PCB production, with thousands of manufacturers specializing in everything from prototype PCBs to high-volume mass production. Major PCB hubs like Shenzhen, Shanghai, and Suzhou host some of the most advanced factories, equipped with automated assembly lines, AI-driven quality control, and cutting-edge fabrication techniques.

2. Cost-Effective Manufacturing Without Compromising Quality

One of the biggest advantages of China PCB manufacturing is its cost efficiency. Due to economies of scale, streamlined supply chains, and government support, Chinese PCB suppliers offer 30-50% lower costs compared to Western manufacturers—without sacrificing quality.

3. Advanced PCB Technologies & Manufacturing Capabilities

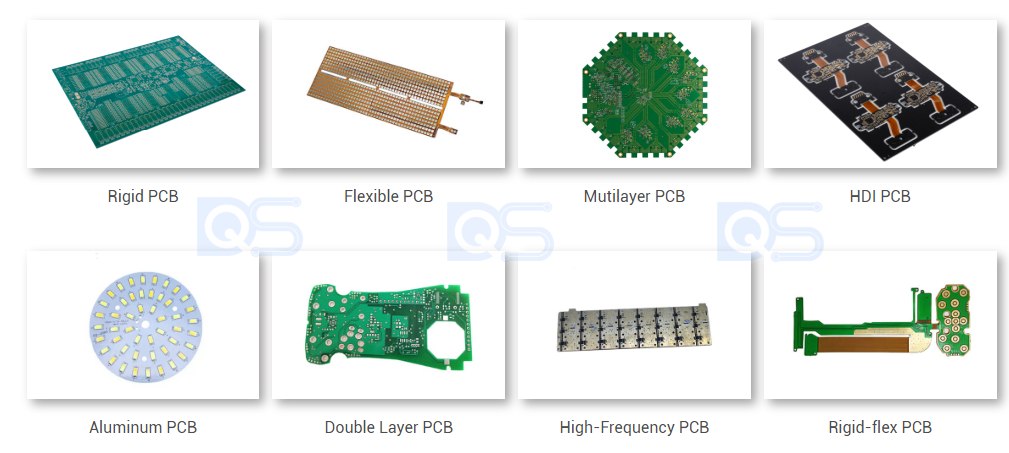

Chinese PCB manufacturers lead in high-tech PCB production, supporting:

4. Rapid Prototyping & Fast Turnaround Times

China’s PCB industry excels in quick-turn PCB fabrication, with some suppliers offering:

5. Strict Quality Control & International Certifications

Reputable Chinese PCB manufacturers adhere to global quality standards, including:

Many factories also implement automated optical inspection (AOI), X-ray testing, and flying probe testing to ensure defect-free boards.

Key Applications of China-Made PCBs

1. Consumer Electronics

2. Automotive & Electric Vehicles (EVs)

3. Medical Devices

4. Industrial & Aerospace

5. Telecommunications & 5G Infrastructure

How to Choose the Right China PCB Manufacturer?

With so many PCB suppliers in China, selecting the best partner requires careful evaluation. Here are key factors to consider:

1. Technical Capabilities

2. Quality Assurance & Testing

3. Production Capacity & Lead Times

4. Pricing & MOQ (Minimum Order Quantity)

5. Customer Support & Communication

DQS ELECTRONIC Group is one the the leading PCB manufacturer from China, the factory spans 12,000 square meters and is equipped with state-of-the-art production machinery. More than 800+ staff online. DQS certified to ISO9001, ISO14001, ISO13485, IATF16949, CE, SGS, and UL standards — ensuring high quality and compliance across industries. No matter small order or bulk orders, Whether simple, high-precision PCBs or complex PCBA assemblies, we deliver on schedule.

Conclusion: Why China Remains the Best Choice for PCB Manufacturing

China’s PCB industry continues to dominate due to its unmatched combination of cost, quality, and speed. Whether you need high-tech HDI boards, flexible circuits, or quick-turn prototypes, Chinese manufacturers provide reliable, scalable, and cost-efficient solutions.

By partnering with a reputable China PCB supplier, businesses can:

✅ Reduce production costs without compromising quality

✅ Access cutting-edge PCB technologies (HDI, Flex, RF)

✅ Speed up time-to-market with rapid prototyping

✅ Scale from prototypes to mass production seamlessly

For companies looking to stay competitive in electronics manufacturing, China remains the top destination for PCB fabrication and assembly.

Contact us today for a free quote! Our email: sales@dqspcba.com

Our hours

24H