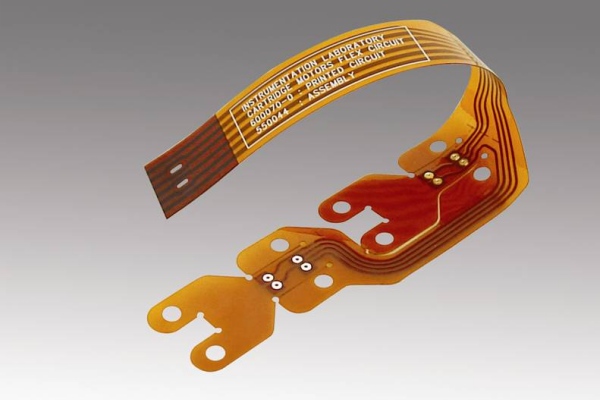

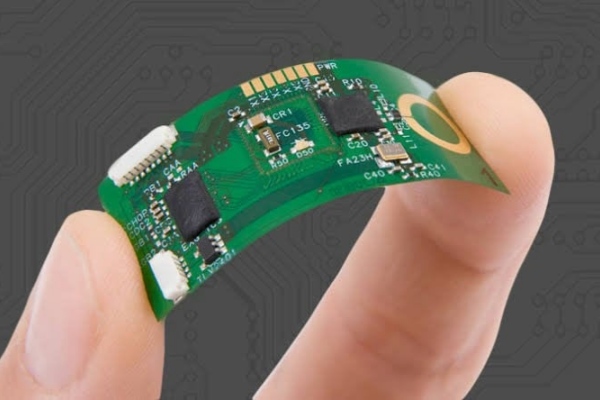

When you take apart a phone or smartwatch, you'll often see a flexible circuit board inside—an FPC (flexible printed circuit board). Many newcomers to the industry are curious: "What materials make FPCs so flexible and bendable?" In reality, the performance of an FPC depends entirely on its raw materials, just as steel and cement are essential for building a house. FPCs also have four core raw materials: base material, copper foil, cover film, and reinforcement plate.

Unlike conventional rigid PCBs, FPCs must bend repeatedly and adapt to tight spaces. Therefore, the raw materials must not only be conductive but also tough and resistant to bending. Poorly selected raw materials, such as a brittle substrate or weak copper foil adhesion, can cause an FPC to break after a few bends or experience poor contact over time.

The four core materials of an FPC are:

1. Substrate: The substrate acts as the skeleton of the FPC. While the skeleton of a standard rigid PCB is made of FR-4 sheet material, the skeleton of an FPC must be flexible and bendable. PI substrate is the most commonly used.

Its functions include: 1. supporting the copper foil, providing a place for the circuits to attach; 2. providing insulation, preventing short circuits between different circuits; and 3. providing toughness, ensuring the FPC remains unbroken even after 10,000 bends.

2. Copper Foil: Copper foil is the conductive wire in the FPC. Like blood vessels in the human body, it transmits current and signals from one component to another.

Purpose: Conducting electricity and transmitting signals. The quality of the copper foil directly affects the FPC's conductive efficiency. For example, low copper foil purity results in high resistance, making signal transmission more susceptible to malfunction.

3. Coversheet: The coversheet acts like a transparent coat over the FPC, applied to the copper foil surface to protect it from scratches and oxidation, while also providing insulation.

Its functions include: 1. protecting the copper foil from corrosion from moisture and dust in the air; 2. increasing the FPC's toughness, preventing cracking during bending; and 3. providing insulation, preventing electric shock from touching the wiring.

4. Reinforcement Plate: A reinforcement plate acts like a steel plate attached to vulnerable areas of the FPC, such as the FPC connector and component soldering points. These areas are subject to high stress and are prone to bending and breaking. Adding a reinforcement plate increases durability.

Purpose: Locally reinforces the FPC's weak points, allowing them to withstand insertion and removal forces and soldering temperatures. For example, without a reinforcement plate, the FPC in a mobile phone charging port would break after just a few insertions.

Our hours

24H