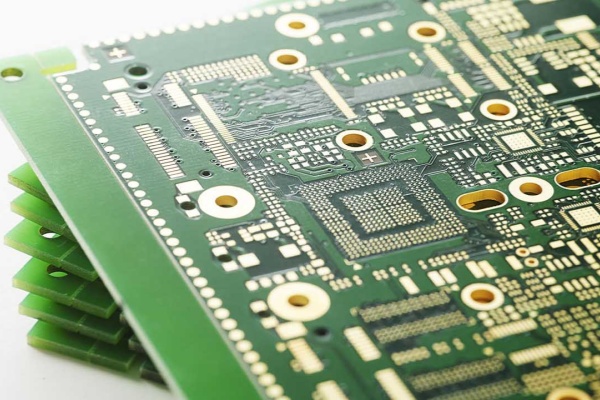

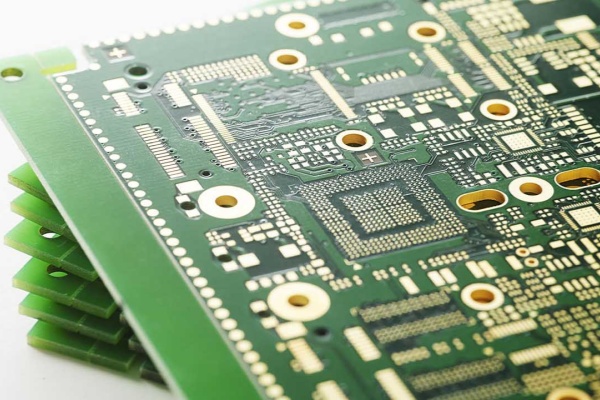

What is PCB immersion gold?

PCB Immersion Gold (also known as ENIG – Electroless Nickel Immersion Gold) is a surface finish process used in printed circuit board (PCB) manufacturing. It involves depositing a thin layer of gold over a nickel layer on the copper pads of a PCB through a chemical plating process.

Why is immersion gold plating necessary?

The copper on circuit boards is primarily pure copper, and copper solder joints are prone to oxidation in the air. This can result in poor conductivity, such as poor solderability or poor contact, thereby reducing the performance of the circuit board.

Therefore, surface treatment of the copper solder joints is necessary. Gold plating involves depositing a layer of gold on the surface. Gold effectively isolates the copper metal from the air, preventing oxidation. Thus, gold plating is a surface treatment method to prevent oxidation, achieved through a chemical reaction that coats the copper surface with a layer of gold, also known as chemical gold plating.

Advantages of Using Immersion Gold (ENIG) Circuit Boards:

Immersion Gold (ENIG – Electroless Nickel Immersion Gold) is one of the most popular surface finishes for PCBs, especially in high-performance and high-reliability applications. Here are its key advantages:

1. Excellent Flat Surface – Ideal for Fine-Pitch Components

The gold layer is extremely thin (0.05–0.2µm) and uniform, making ENIG ideal for:

- Fine-pitch components (small ICs, BGAs, QFNs)

- High-density interconnect (HDI) PCBs

- Laser-drilled microvias

2. Superior Solderability & Reliable Joints

- Gold prevents oxidation of the underlying nickel, ensuring strong and reliable solder joints.

- Compatible with lead-free (RoHS) soldering processes.

- Reduces the risk of solder bridging in dense PCB layouts.

3. Long Shelf Life & Oxidation Resistance

- Gold is highly resistant to corrosion, allowing ENIG PCBs to be stored for 6–12 months without degradation.

- Unlike OSP (Organic Solderability Preservative), which degrades quickly, ENIG remains solderable for extended periods.

4. Good Electrical Conductivity

Gold is an excellent conductor, making ENIG suitable for:

- High-frequency circuits (RF, microwave PCBs)

- Signal integrity-critical applications (server motherboards, telecom devices)

5. Compatibility with Multiple Assembly Processes

Works well with:

- Surface Mount Technology (SMT)

- Through-Hole Technology (THT)

- Wire Bonding (for semiconductor packaging)

6. Suitable for Gold-Plated Contacts & Connectors

ENIG provides a smooth, wear-resistant surface for:

- Edge connectors

- Test points

- Keypads & switches

7. Environmentally Friendly (Compared to Some Alternatives)

- Unlike HASL (which may use lead), ENIG is lead-free and RoHS-compliant.

- No flux residues (unlike HASL), reducing cleaning requirements.

What's the difference between immerson gold and golden finger?

Gold Fingers are the gold-plated contact pads along the edges of printed circuit boards (PCBs), designed to serve as durable electrical connectors for repeated insertion and removal. They are commonly used in devices where reliable signal transmission and mechanical wear resistance are critical.

Comparison Table

|

Feature

|

Immersion Gold (ENIG)

|

Gold Fingers (Hard Gold)

|

|

Gold Thickness

|

0.05–0.2 µm

|

0.5–3 µm

|

|

Plating Method

|

Electroless (chemical)

|

Electroplated (electrical)

|

|

Hardness

|

Soft

|

Hard (alloyed with cobalt/nickel)

|

|

Primary Use

|

Solderable surface finish

|

Wear-resistant electrical contacts

|

|

Cost

|

Moderate

|

Higher (due to thicker gold)

|

|

Typical Applications

|

Consumer electronics, IoT

|

RAM modules, PCIe slots, industrial connectors

|

DQS ELECTRONIC GROUP is a professional PCB manufacture from China, we can produce 1-108 layer PCBs. The sureface finishing we can make : HASL(with Pb free), Plated Ni/Au, ENIG, Immersion Tin, Golden Finger,Immersion Ag, OSP,etc. We have passed ISO9001, ISO14001, ISO13485, UL for USA, UL for Canada, IATF16949. We mainly build volume production& high precision PCBs.

Welcome to send your Gerber file for check and get free quote. here is our offical email: sales@dqspcab.com