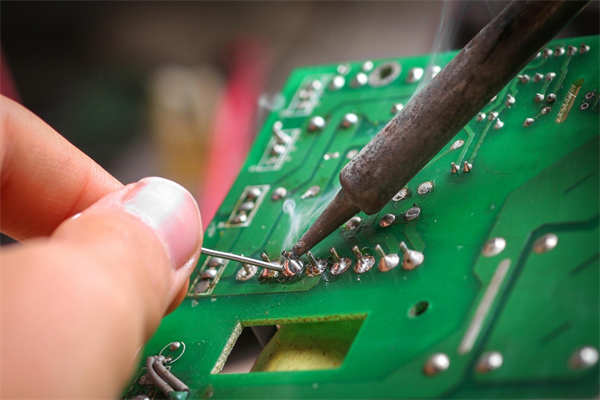

Spot welding is a technology that connects metals by local heating, and is mainly used for connecting thin sheet metals. Its working principle is to use two electrodes to apply high voltage current in a short time (usually 0.01-0.5 seconds) to make the contact point melt instantly at high temperature, and form a weld under pressure.

Features and advantages:

· Fast welding speed and high efficiency

· Small heat affected zone and small workpiece deformation

· No need to add solder, lower cost

· Easy to realize automated production

Typical Applications:

Car body welding in automobile manufacturing, connection of electronic components, assembly of home appliance housing, etc. In the automotive industry, an ordinary car usually contains 3000-5000 spot welds.

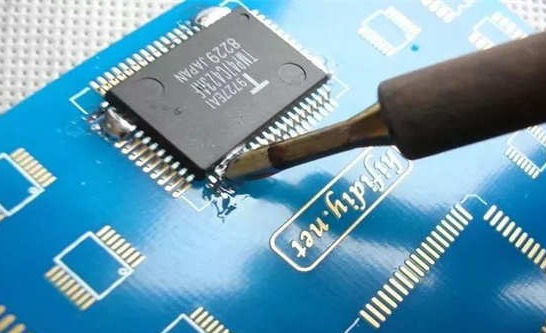

Drag soldering (a variant of wave soldering) is a widely used soldering method in the electronics manufacturing industry, especially suitable for batch soldering of through-hole components (THT). During the operation, the PCB board with components inserted is dragged through the molten solder wave at a certain angle and speed.

Key points of the process:

1. Preheating stage: The PCB board first passes through the preheating zone, and the temperature is usually controlled at 90-130℃

2. Flux spraying: ensures a clean soldering surface and improves wetting

3. Soldering stage: The contact time between the board and the solder wave is about 3-5 seconds

4. Cooling and curing: natural cooling or forced air cooling

Key to quality control:

· Soldering temperature (usually 245-265℃)

· Conveyor belt angle (4-7° is appropriate)

· Immersion depth (1/2-2/3 of the plate thickness)

· Conveying speed (1.2-1.8m/min)

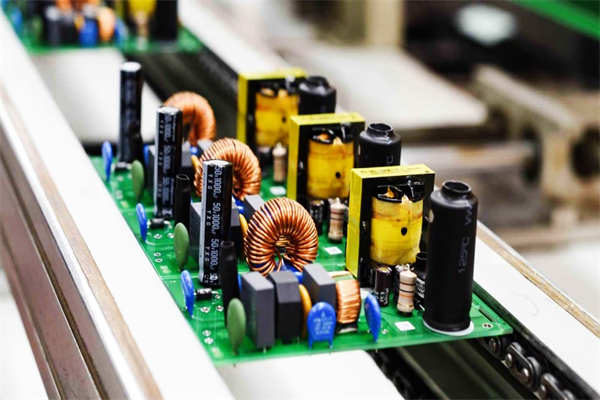

Automatic DIP (Dual In-line Package) welding is a highly efficient welding system designed specifically for dual in-line package components, which realizes a fully automated process from plug-in to welding.

System composition:

· Automatic feeding device

· Precision plug-in robot

· Multi-zone preheating system

· Selective wave soldering module

· Automatic detection and sorting unit

Technical advantages:

1. The connection consistency is as high as 99.5% or more

2. Production efficiency is 5-8 times higher than manual operation

3. Programmable control, flexible to adapt to different component specifications

4. Integrated visual inspection to monitor welding quality in real time

Industry Applications:

Consumer Electronics、Industrial control equipment、In the mass production field of automotive electronic modules, automatic DIP welding has shown significant advantages, especially for DIP package components with many pins and dense arrangement.

|

Characteristic |

Spot Welding |

Drag Soldering |

Automatic DIP welding |

|

Applicable Materials |

Sheet Metal |

PCB+THT Components |

DIP Package Components |

|

Welding Speed |

0.1-0.5 seconds/point |

1-2 minutes/plate |

30-60 seconds/plate |

|

Equipment Cost |

Middle |

Medium to High |

High |

|

Suitable for Batch |

Medium to Large |

Large |

Extra Large |

|

Accuracy Requirements |

Generally |

Higher |

High |

Select Suggestion:

· Spot welding is preferred for metal parts connection

· Through-hole component mass production is suitable for drag soldering

· High density DIP components selection automatic DIP soldering

· Selective wave soldering can be considered for mixed technology (SMT + THT) boards

These three welding technologies have their own strengths and together constitute the connection technology system of modern electronic manufacturing. Enterprises should choose the most suitable welding solution according to product characteristics and production requirements, and combine multiple processes when necessary to achieve the best balance between quality and benefit.

Our hours

24H